SUMMER LIMITED EDITION VAPES NOW AVAILABLE

What is a Chemical Raw Materials Manufacturer and Their Role?

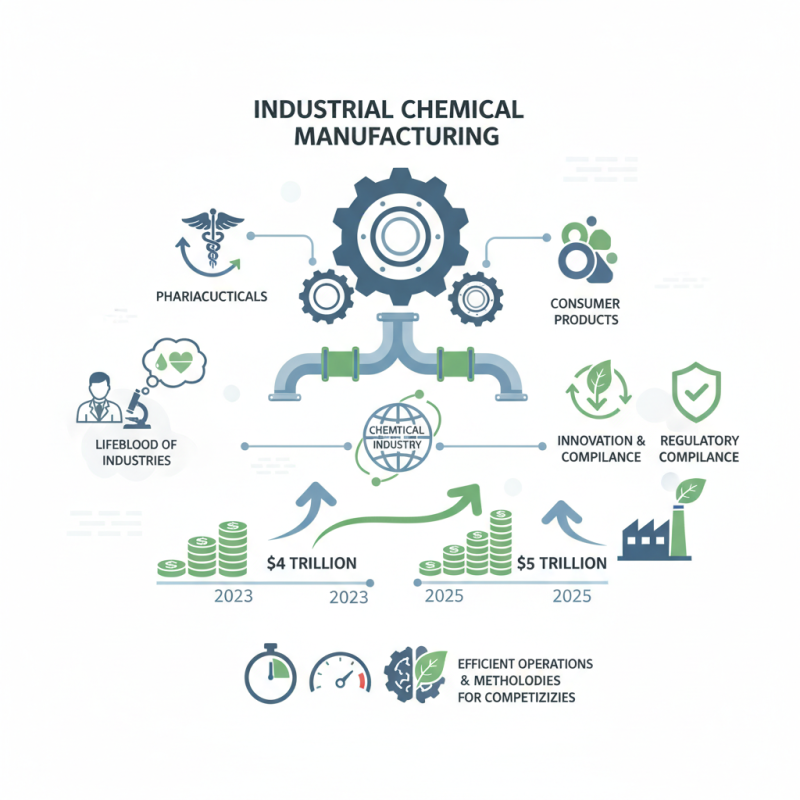

In the complex landscape of industrial production, the role of a chemical raw materials manufacturer is crucial. According to a recent report by ICCA, the global chemical industry was valued at approximately $4 trillion in 2023, showcasing its significant economic impact. These manufacturers supply essential materials for various sectors, including pharmaceuticals, agriculture, and consumer products.

Dr. Emily Johnson, a leading expert in chemical manufacturing, stated, "Chemical raw materials are the lifeblood of countless industries." This highlights their importance and the need for reliable suppliers. However, challenges such as sustainability and regulatory compliance are ever-present. The pressure to innovate and reduce environmental footprints creates a dynamic yet challenging business environment.

The market continues to grow, yet not all manufacturers keep pace with industry demands. A report from MarketsandMarkets indicates that the chemical raw materials market is expected to reach $5 trillion by 2025, emphasizing the need for efficient operations. As companies strive to enhance their processes, reflection on their methodologies becomes critical to staying competitive.

Definition of Chemical Raw Materials Manufacturer

chemical raw materials manufacturers play a key role in the global economy. They provide essential components for various industries, including pharmaceuticals, agriculture, and construction. These manufacturers produce a wide range of substances, from polymers to specialty chemicals. According to a recent market report, the global chemical manufacturing industry is projected to grow at a CAGR of 4.2% from 2021 to 2028. This growth is driven by increasing demand in emerging markets.

These manufacturers often face challenges such as fluctuating raw material prices and environmental regulations. Innovation is crucial. Many companies are investing in sustainable practices to reduce their carbon footprint. However, some struggle to keep up with the pace of change. The shift towards greener chemicals could transform supply chains, but adaptation takes time.

Furthermore, chemical raw materials manufacturers must ensure product quality and compliance with safety standards. The industry operates within strict guidelines. Nonetheless, lapses can occur, leading to recalls or reputational damage. Balancing efficiency with safety is a constant challenge. In a competitive landscape, continuous improvement is vital for long-term success.

Chemical Raw Materials Production by Industry in 2022

This chart illustrates the production volume of chemical raw materials by different industries in 2022, showing the importance of each sector in the overall market.

Key Functions of Chemical Raw Materials Manufacturers

Chemical raw materials manufacturers play a vital role in various industries. They produce essential inputs for sectors like pharmaceuticals, agriculture, and construction. These materials include basic chemicals, intermediates, and specialized compounds. Manufacturers focus on quality and consistency. This ensures that products meet specific industry standards.

One key function of these manufacturers is research and development. They continuously innovate new materials. This helps to address evolving market needs and environmental concerns. Another critical duty is supply chain management. Manufacturers must monitor raw material availability and pricing. Fluctuations in supply can impact production schedules significantly. It creates challenges when demand surges unexpectedly.

Sustainability is increasingly important. Manufacturers are exploring greener processes. They seek alternatives to hazardous substances. This often requires investment in new technologies. Yet, balancing cost and sustainability can be difficult. Manufacturers may struggle to maintain profitability while adopting eco-friendly practices. Community engagement is another area for improvement. Often, local impacts are overlooked in decision-making. A more inclusive approach could foster better relationships with communities.

What is a Chemical Raw Materials Manufacturer and Their Role? - Key Functions of Chemical Raw Materials Manufacturers

| Function | Description | Importance |

|---|---|---|

| Production | Manufacturing chemical raw materials in bulk for various industries. | Ensures a steady supply of materials for downstream processes. |

| Quality Control | Monitoring and testing materials to meet industry standards. | Aids in maintaining product quality and regulatory compliance. |

| Research and Development | Innovating new materials and improving existing products. | Facilitates industry growth and adaptation to market needs. |

| Logistics | Managing the distribution and transportation of raw materials. | Ensures timely delivery to clients and reduces lead times. |

| Customer Support | Providing assistance and technical support to clients. | Enhances client satisfaction and addresses technical issues effectively. |

Types of Chemical Raw Materials Produced

Chemical raw materials play a crucial role in various industries. Manufacturers of these materials focus on producing essential components. These include solvents, acids, and polymers. Solvents are often used in paints and coatings. They help dissolve or disperse other materials. Acids are vital for many chemical reactions in labs and industry.

While some manufacturers excel in producing one type of raw material, others may diversify. It is common to see firms specializing in organic chemicals or inorganic chemicals. Organic chemicals include compounds derived from living organisms. In contrast, inorganic chemicals encompass minerals and metals. The choice of focus affects production methods and sustainability practices.

Tips: Always consider the source of your raw materials. A local supplier may reduce transportation costs. Additionally, prioritize eco-friendly options whenever possible. Focus on quality as well. Compromising on raw material quality can lead to issues down the line. Remember, not all materials are equal. Some may perform better in specific applications. Regularly review your supplier capabilities to ensure they align with your needs.

Importance of Chemical Raw Materials in Various Industries

Chemical raw materials play a vital role across various industries. They serve as the building blocks for countless products. From plastics to pharmaceuticals, these materials are essential. Manufacturers supply them to sectors like construction, agriculture, and textiles. Each industry relies on these materials to innovate and improve efficiency.

In the automotive sector, for instance, chemical raw materials are crucial for producing parts. Polymers and composites enhance durability and performance. Yet, the process can be flawed. Some manufacturers may overlook sustainability. This oversight can lead to environmental issues. In agriculture, fertilizers and pesticides derived from chemicals are necessary for crop production. However, their use can also lead to soil degradation and water pollution if not managed properly.

Despite their importance, the industry faces challenges. Safety standards and regulations are often evolving. Manufacturers must constantly adapt. Balancing innovation and responsible practices is not easy. There is a need for more sustainable options that do not compromise quality. As the demand for chemical raw materials increases, the industry must reflect on its methods and impacts.

Challenges Faced by Chemical Raw Materials Manufacturers

Chemical raw materials manufacturers face numerous challenges in today's dynamic market. Sourcing quality raw materials is often a struggle. Price volatility can impact production costs significantly. Manufacturers must keep up with fluctuating prices to remain competitive. Additionally, securing a reliable supply chain is essential yet often complicated. Disruptions can arise from natural disasters or geopolitical tensions.

Another challenge is regulatory compliance. Strict regulations govern the production and handling of chemicals. Staying compliant can require significant investments in training and technology. Many manufacturers find it difficult to navigate these complex requirements. Environmental concerns also pose a challenge.

Consumers are increasingly demanding sustainable practices, pushing manufacturers to adapt. However, implementing greener processes can be expensive and time-consuming.

Talent acquisition is a persistent issue too. The industry often struggles to attract skilled workers. Many positions require specialized knowledge and training. Manufacturers must compete for a limited talent pool. Balancing innovation with operational efficiency is another complex task.

Finding the right technology can enhance productivity but often requires upfront investment. The road ahead may be challenging, but reflection can lead to better strategies for future success.